Services

Costruzione Ricambi Macchine Industriali

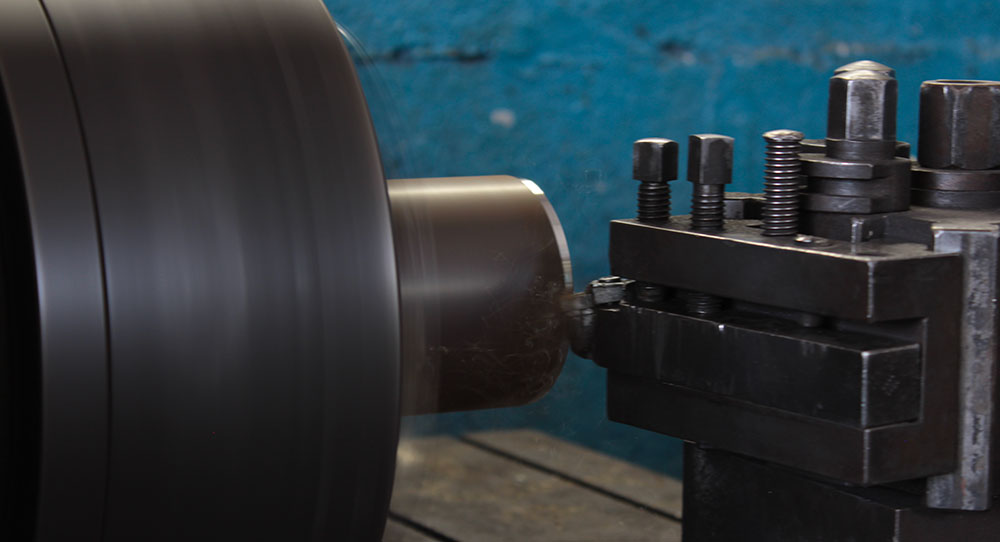

The Industrial Machinery Spare Parts Construction offers its customers the service light carpentry, ensuring maximum flexibility and ensuring a wide range of solutions and possibilities for realization.

Light carpentry